¶ INTRODUCTION

¶ HOW TO GET HELP

If you need assistance with your build you can head over to the DOOMCUBE Discord server and post your questions (typically in the #micron_build_questions channel). It is the primary help channel for the Micron! You can also check the Github page for the latest releases.

¶ DISCO? OH… DISCORD

If you need assistance with your build you can head over to the DOOMCUBE Discord server and post your questions (typically in the #micron_build_questions channel). It is the primary help channel for the Micron!

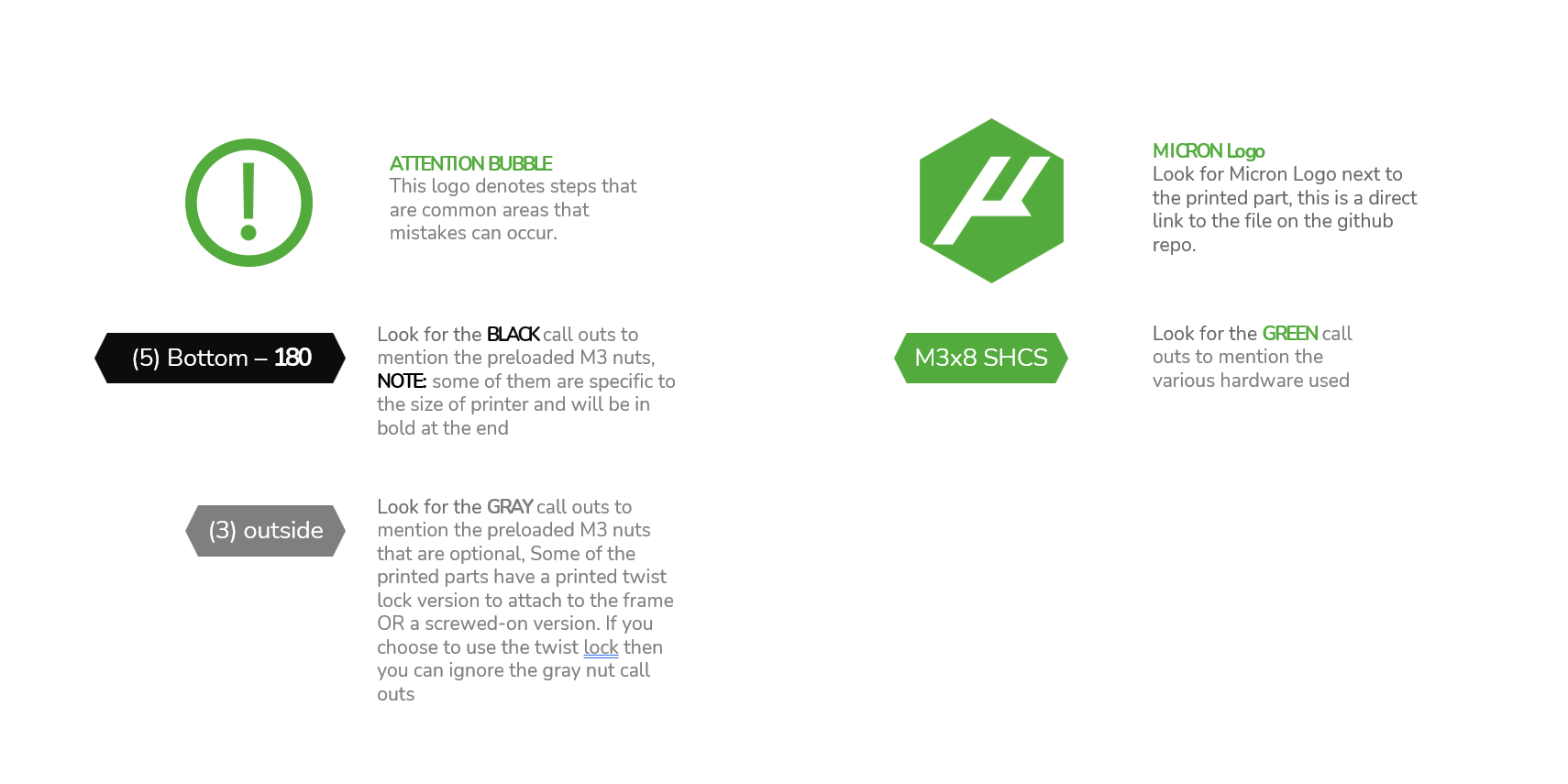

¶ STL FILE KEY

| Primary Color | Accent Color | Quantity Required |

|---|---|---|

| z_drive_main_a_x2.stl | [a]_z_drive_baseplate_a_x2.stl | [a]_z_drive_baseplate_a_x2.stl |

| These files will have nothing at the start of the filename. | These files will have [a] to the front to mention that they are intended to be printed with an accent color. | If a file ends with xN, you need to print N number of that file |

¶ PRINT GUIDELINES

| FDM MATERIAL | INFILL TYPE | LAYER HEIGHT | WALL COUNT | EXTRUSION WIDTH | INFILL PERCENTAGE | SOLID TOP/BOTTOM LAYERS | SUPPORTS REQUIRED |

|---|---|---|---|---|---|---|---|

| ABS/ASA | Grid, Cubic, Adaptive Cubic | Recommended: 0.2mm | Recommended: 4 | Recommended: Forced 0.4mm | Recommended: 40% | Recommended: 5 | If the part needs supports, they are built into the model. |

¶ Hardware References

¶ FASTENERS

| BUTTON HEAD CAP SCREW (BHCS) | FLAT HEAD CAP SCREW (FHCS) | SOCKET HEAD CAP SCREW (SHCS) | GRUB SCREW (GS) |

| Metric fastener with a domed shaped head and hex drive. Most commonly found in locations where M3 fasteners are used. | Metric fastener with a cone shaped head and a flat top. | Metric fastener with a cylindrical head and hex drive. The most common fastener used on the Voron. | Metric Socket Cup Point Set Screws (also called Hollow Point Grub Screws) are fitted with a concave cup point, which allows them to fit closely against a rounded surface such as a motor shaft. |

| ISO 7380-1 | ISO 10642 | ISO 4762 / DIN 912 | ISO 4029/ DIN 916 |

| !HEX NUT IMAGE | !HEAT SET INSERT IMAGE | !SELF TAPPING SCREW IMAGE | !PULLEY IMAGE |

|---|---|---|---|

| M3 HEX NUT | HEAT SET INSERT | SELF TAPPING SCREW | PULLEY |

| Hex nuts couple with bolts to create a tight, secure joint. You’ll see these used in both M2 and M3 variants throughout this guide. | Heat the inserts with a soldering iron so that they melt the plastic when installed. As the plastic cools, it solidifies around the knurls and ridges on the insert for excellent resistance to both torque and pull-out. | Fastener with a pronounced thread profile that is screwed directly into plastic. | GT2 pulley used on the motion system of the Micron. | |

| ISO 4032 / DIN 934 |

| F623 BEARING | 625 BEARING | 5MM X 47-50MM SHAFT | M3 SHIM |

| A ball bearing with a 3mm ID and flange for containing the belt used in various gantry locations. | A ball bearing with used in the Z drive. | Steel shaft, 5mm in diameter, 47mm-50mm long with a flat ground on it used in the Z drive shaft assembly. | Not to be confused with stamped washers. These are used in all M3 call-out locations in this manual. |

| 3x6x0.5 DIN 988 |

¶ Blind Joints

BLIND JOINT BASICS

Blind Joints provide a cost-effective and rigid assembly method. The head of the BHCS is slid into the channel of another extrusion and securely fastened through a small access hole in the extrusion. If you’ve never assembled one before we recommend you watch the linked guide.

¶ Extrusion Prep

SORT EXTRUSIONS

Collect your extrusions and sort them by length. We will highlight the extrusions used in each step and label them as shown on this page.

EXTRUSION CALL-OUTS

To avoid confusion, we will call out the extrusions by the names shown on these reference pages. To help assembly along you may want to label the extrusions or print the reference page for a faster lookup

(Note: the scaling of the images might not function as intended when viewed on mobile screens. Refer to measurements and references below.)

| A | B | C | D | E |

|---|---|---|---|---|

| 350 mm | 280 mm | 265 mm | 250 mm | 180 mm |

| ×4 | ×10 | ×2 | ×2 | ×1 |

(!!!! Need to find a convenient way to implement this system in the wiki. Below callout could be one way to do it.)

¶ Extrusion Prep - Reference

¶ BED EXTRUSIONS?

Some frame kits come with bed extrusions that are mounted using blind joints. These will end up being 2 longer extrusions and 8 B extrusions.

MULTIPLE VIEWS

The views shown are the left, front, right, and bottom views of each extrusion.

ALL UNITS ARE METRIC

If a unit is not specified assume it’s metric.